The high cost of advanced biomedical research and treatments limits access for patients worldwide. One way NMH aims to address this challenge is by offering high-performance magnetic nanoparticles at a significantly lower cost. We used our Microwave-Thermal Treatment Method (MTTM) to produce high-quality Nano-ferrites and Nano-orthoferrites, which are not manufactured through the lengthy and costly synthesis processes of conventional methods. This approach reduces costs and creates new opportunities in diagnostics and Targeted Drug Delivery, proving that quality and affordability can go hand in hand.

Technical Detail Driving Cost Reduction in Advanced Materials

This section studies the direct relationship between cost savings for healthcare and pharmaceutical manufacturers due to the proprietary production methods of NMH. Savings are made through lowering energy use, time, and reagent expenses compared to conventional high-temperature, complicated synthesis approaches.

Lower Manufacturing Costs through Shorter Production Times

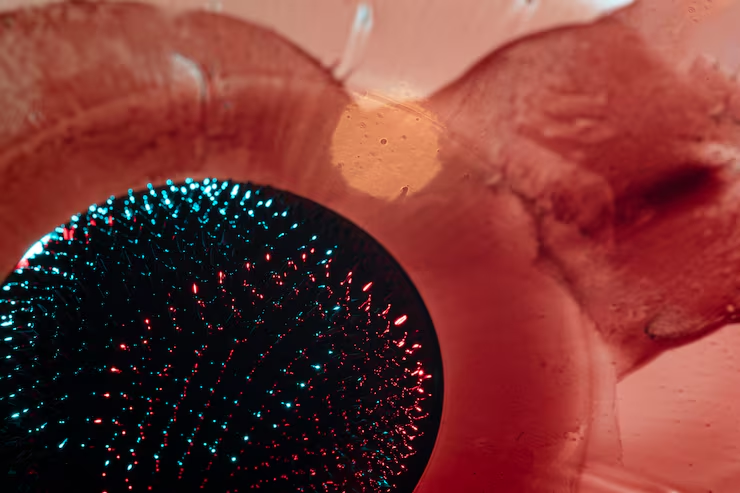

Our MTTM approach takes advantage of the fact that assistance on the microwave scale helps synthesize magnetic nanoparticles in a fraction of the time compared to traditional thermal treatments. A reduction in the length of production cycles decreases the amount of energy and the number of labor hours, allowing us to attract competitive prices and substantially lower the cost of operations.

High Purity Reduces Post-Production Processing

The methods of Nano-ferrites and Nano-orthoferrites powder synthesis that are controlled in NMH guarantee high purity. This minimizes the supply of long purification post-production, which is usually expensive in sensitive medical procedures. Reduced processing implies reduced overheads and increased operational efficiency.

Scalability Lowers Unit Price

We can easily scale up our production techniques, which will enable us to move easily between production on a laboratory scale and high production volume. This scalability allows NMH to enjoy the economies of scale and makes the unit cost of the materials low and proper, thus we can be able to satisfy the increasing demand for high-quality nanoparticles at a favorable price.

Eliminating Toxic Reagents and Waste Disposal Costs

Traditional synthesis techniques tend to use toxic or high-priced chemical reagents, thereby increasing the cost of acquisition and the charges of disposal. The supportable manufacturing process by NMH minimizes the usage of such reagents, which reduces the cost of materials, limits disposal costs, and leads to cost reduction of production.

Real-World Expertise and Value in Biomedical Targeted Drug Delivery

This section explores how the decreased cost and superior quality of NMH’s magnetic nanoparticles increase Targeted Drug Delivery and medical imaging, making these advanced technologies more accessible for research and clinical trials. This affordability accelerates their path to the market, benefiting global healthcare.

Accelerating Research into Targeted Drug Delivery

Targeted Drug Delivery systems are often restricted in the scope of preclinical and clinical trials because of the high material costs. By offering affordable and dependable Nano-ferrites, NMH can allow researchers to carry out larger-scale studies, speeding up the validation process of new medications and accelerating the introduction of advanced therapeutics to the market even faster.

Enabling Affordable MRI Contrast Agents

The high magnetic responsiveness and homogeneity of the nanoparticles in NMH render them the best for use as MRI contrast agents. The cost of producing diagnostic agents is also reduced because of our capability to provide high-performance materials at low prices, which helps reduce the cost of medical imaging procedures.

A Strategic Advantage for Medical Device Manufacturers

Medical equipment producers creating new-generation devices, such as biosensors and magnetic separation devices, are direct beneficiaries of the consistency and low cost of NMH. The availability of quality nano-ferrites helps to improve the operation of these devices at a fee that does not push up the final product cost, thus giving operational efficiency advantages throughout the medical supply chain.

PCT-Patented Quality Assurance

The PCT-patented synthesis method used in the NMH system guarantees the uniform quality of our nanoparticles. This protection is accorded internationally, making biomedical partners assured that the materials they buy are made by a special and quality-guaranteed process.

Closing Thoughts:

NMH proves that cost reduction and performance are not mutually exclusive in the field of magnetic nanoparticles (MNPs). Our MTTM method is a technological breakthrough that lowers economic barriers to advanced medical solutions. This commitment to affordability drives innovation in diagnostics and Targeted Drug Delivery.

Conclusion:

NMH is placed as a leader in supplying cost-effective, high-purity nano-ferrites essential for the biomedical sector. Our expertise in synthesis ensures exceptional uniformity, stability, and reliability of our materials, accelerating medical breakthroughs while maintaining cost efficiency.